Clayborn Lab - A World of applications

Aerospace

Satellites, Vacuum Chambers, Testing, Laboratory

Automotive

Fuel Cell Development, Cold Chamber testing

Construction

Concrete Curing, Ground Thaw, Hot Box Heater

Composites

Adhesive Application, Epoxy Transfer, 2-part Spray

Environmental

EPA-required Testing, Solar, Biofuel Development, Diesel Emissions

Food Industry

Viscosity Control, Production Technology

Gas Samples

Emission Testing, Stack Samples, Analyzer Components, Field Tests

Government

International Space Station, Meteorological Analysis

Industrial

Machinery, Systems Engineering, Semiconductors

Laboratory

Thermal Testing, Non-Condensate, Instrumentation, Electron Microscopes

Medical

Flow Control, Instrumentation, Scientific Research, Optical Resolution

Pharmaceutical

Production Machinery, R&D, Test

Transportation

Train Car Defrost System, Aviation Freeze Protect, Tank Batteries

University

Mechanical, Chemical, Electrical

How To

How to Install Terminals and Make Heating Tape Connections

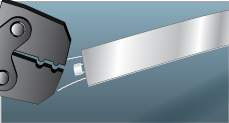

1. Push lead wires through terminal block holes. Strip lead wire ends and crimp butt connectors onto lead wires.

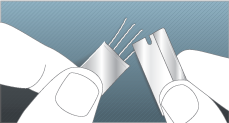

2. Split tape and open using tweezers. Dull tweezers are better than very sharp tweezers.

3. Cut back top and bottom laminations leaving wire ends exposed approx. 3/16" for small terminals and 1/4" for large terminals. Scrape enamel from wire ends using razor blade.

4. When using 4-wire tape in full series connection, crimp half of a #092 connector onto center 2 wires and trim short.

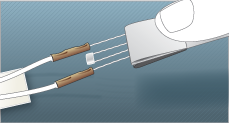

5. Crimp lead wires onto heaters. To avoid breaking, do not crimp heater wire too hard!

6. Strip paper liner back about 1" from tape lead end. Push terminal block over connectors.

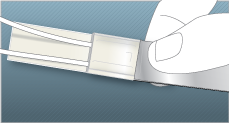

7. Press heater tape onto self-adhesive terminal flap.

8. If desired, apply RTV Sealant (available from Clayborn) over terminal block end.

Download PDF

Download PDF